CONCRETE CLEANING, POLISHING, STAINING & FINISHING

Concrete is very durable and extremely resistant to wear and tear. Just like any flooring material, some finishes are better in certain locations than others. GK’s will help educate you on the various concrete finishing options, so you can make a well informed decision on what is best for you. Whether you’re looking for something more durable or for that one-of-a-kind glamorous floor, GK’s can help you choose the best concrete finish!

GK’s has the expertise, equipment and the knowledge to perform many specialized projects. If you want it done right the first time – call us! GK’s has invested the time and money to do things the right way! We have numerous options for restoring and renewing your home or business’ concrete. Please read about the most common finishing options we offer below. Also, take a look at our picture galleries to see if we have completed a project similar to what you are looking to achieve. Even if you don’t see the specific concrete finish listed here, we can most likely handle it – please be sure to ask!

MOST COMMON CONCRETE FINISHING OPTIONS

Every concrete surface is different, from the makeup of the concrete to all of the variables within your home or facility (foot traffic, weather, ongoing maintenance plan, etc…). We take all of the guesses out of the equation and present only the most viable concrete refinishing options to our customers. Since every surface is different, very few projects are similar in how they are refinished or maintained.

Refinishing and Maintenance for these Finishes:

- Polished Concrete

- Acid Stain and Acetone Dye Application

- Epoxy, Urethane and Polyaspartic Coatings

- Stamped Concrete Maintenance

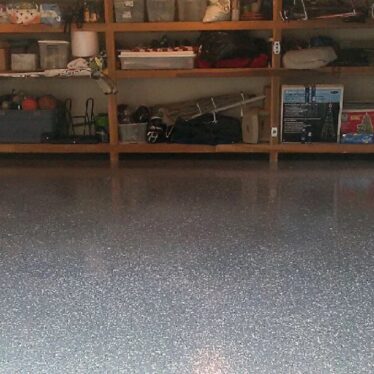

- Garage Floor Finishes

- Basement Finishes

- Industrial and Commercial Finishes

Please click on any one of the 6 red topics below for more information:

CONCRETE FINISHING OPTIONS

- Concrete is cleaned with an acidic restoration cleaner and a 3500 psi heated and pressurized machine.

- The concrete was ground smooth

- The concrete was honed 1 finer stage

- An Acid Stain or Acetone Dye was applied

- A clear, two-part urethane topcoat was applied

- The concrete was ground smooth

- The concrete was honed 2 finer stages

- A Liquid Densifier was applied

- Semi-transparent or Acetone Dye – OPTIONAL

- A Lithium Silicate Protective Finish was applied

- The concrete was ground smooth

- All joints, holes and cracks were filled

- An epoxy primer was applied

- A colored, two-part epoxy was applied with decorative flakes

- A clear, two-part urethane topcoat was applied

- The concrete was ground smooth

- All joints, holes and cracks were filled

- An epoxy primer was applied

- A colored, two-part metallic epoxy was applied

- A clear, two-part urethane topcoat was applied

- The concrete was stripped to remove old coatings (OPTIONAL)

- The concrete was cleaned with a heated & pressurized cleaning system

- A new dye or stain was applied to restore color to the concrete (OPTIONAL)

- A solvent-based (exterior grade) acrylic sealer was applied